Single tree | Two trees | Three trees | Four trees

Two tree support examples

Fixing a platform between two trees is perhaps the ideal arrangement for a treehouse builder. Flexible joints are required but movement is much more predictable than systems involving more trees, and you will be able to build a larger floor space than using only one tree.

Small treehouses

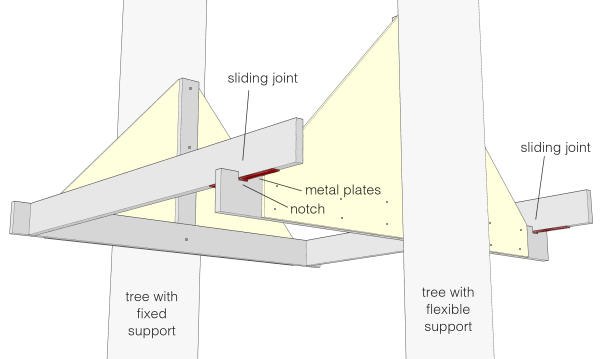

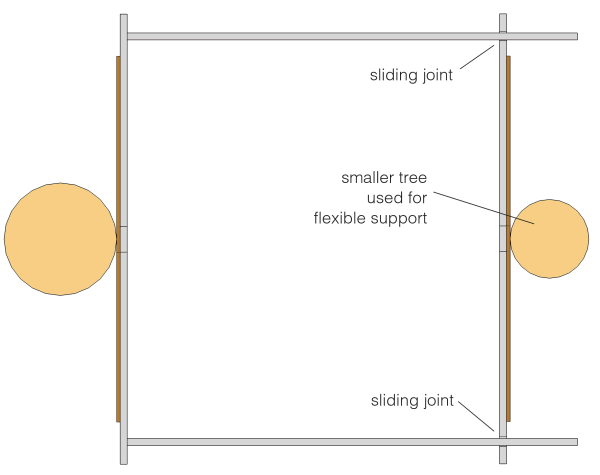

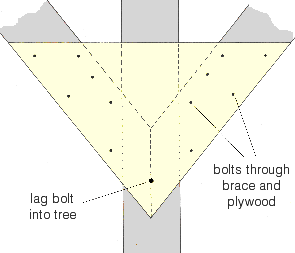

Treehouses that will not be very large can be supported quite simply between two trees. Two large triangles of thick exterior plywood (at least ¾") can be bolted securely to a 2x8 beam as shown below. A lag bolt is fitted through the top and bottom of each triangle into the tree trunks. This allows plenty of space to avoid compartmentalisation. In the diagram below, two further beams are bolted to the nearest support and are allowed to slide on metal plates fitted to the right hand support.

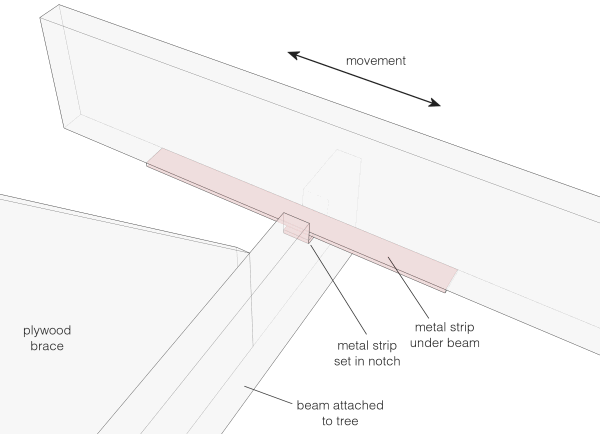

The beam attached to the second tree has notches cut near the ends, to guide the sliding beams. The rubbing surfaces are fitted with ¼" steel plates to protect the wood from wear.

Technical notes

- The lower lag bolts pass through the beam as well as the plywood

- Use washers on all bolts

- The sliding beams should have a metal plate fitted so that the joint is metal to metal and the wood will not be worn away

- The larger the plywood triangles, the stronger the supports will be

- The right hand triangle is fitted lower than the first so that the sliding beams will be level when fitted

Once you set up this frame, fill in the floor with 2x4 joists. You must leave a space between the right hand side of your floor and the tree to allow for movement of the floor backwards and forwards. Stops may be fitted to the right hand bracket to prevent the sliding beams slipping off the end, but in any event there should always be enough length on the beam to accommodate this. This method of support would be suitable for small treehouses with a floor space in the region of 6'x4'.

Larger treehouses

Brackets made from steel can be used in a similar way to the plywood triangle method above for larger structures. There are various other possibilities with brackets that take advantage of the high strength of steel. Traditionally, wooden braces are often used to support treehouse beams. These are cheap and can be adapted to different angles and heights. A relatively new variant is to use steel cables to suspend the ends of the support beam from points higher up the tree.

Metal supports

It is best to get a professional to assess the strength of the pieces you use as safety is always important. Thick sheet metal can be used for a simple enhancement over plywood, but it will be very heavy. Two pieces of metal beam (I-beam, channel, or square section) can be welded together in a '+' shape for an effective but easy bracket. One of these on each tree will form the basis for a larger platform, the size of which is only limited by the quality and size of the bracket. Use the metal brackets to bolt 2x8 or larger beams onto as extension arms. These arms can then be used as in the above diagram to form a framework that slides. As the welds are critical to the safety of the treehouse, it's a good idea to use a backup support (such as cable) in case of weld failure in the future.

More about metal brackets.

Wooden knee braces

Knee braces can provide support for heavier treehouses than the plywood, and for less money than equivalent metal brackets. The floor and its sliding mechanism work in the same way as above, but braces are used to hold up the end of the main support beams instead of the plywood. See the knee braces page for more information. Attempt to arrange the braces so they transmit their load directly into the tree, instead of relying entirely on the strength of lag bolts. If this is not possible, bolt some thick ply or a piece of 2x8 between braces to help them bear against each other as shown in the diagram below.

More about knee braces.

Cables

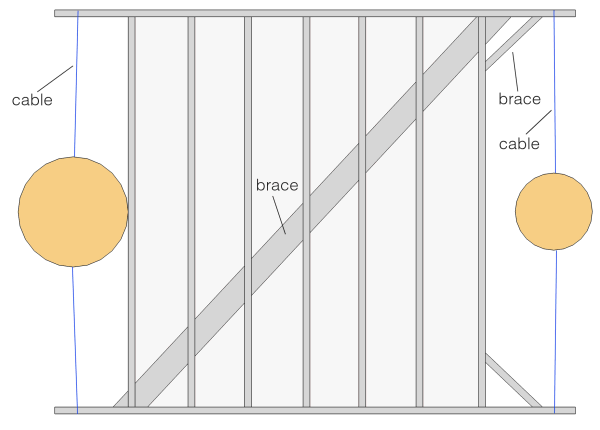

Again, cables provide an alternative to standard fastenings. In the example below the left hand tree has been arbitrarily chosen as the one for the static joint. One beam is lag bolted to this tree, and two cables provide static support for the left hand corners of the frame.

Movement is accepted at the right hand tree. The floor network is supported by its furthest right corners from cables fitted to eye bolts higher up the tree (at least 6 feet higher in this situation). A brace runs under the framework to prevent twisting. The floor surface itself (usually plywood) will provide extra protection. The small braces used in the right hand corners help to resist the inward force from the cable, which is supporting each side from an angle of around 60°.

More about cables.

Single tree | Two trees | Three trees | Four trees